Quality

Metallurgy

Metallurgy

Outlined below are some of the tests performed at Maycast-Nokes. Tensile testing, metallography and hardness testing are all qualified under the stringent requirements of our Nadcap Heat Treatment approval.

Outlined below are some of the tests performed at Maycast-Nokes. Tensile testing, metallography and hardness testing are all qualified under the stringent requirements of our Nadcap Heat Treatment approval.

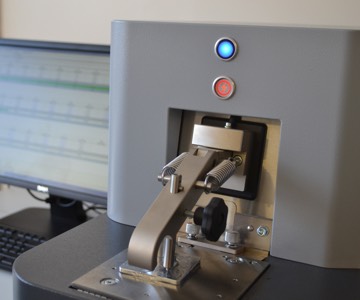

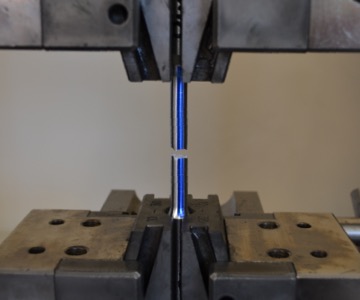

Tensile Testing

Maycast-Nokes performs tensile testing up to 100KN capacity at ambient temperature. Tests can be performed in accordance with:

BS EN 10002

BS EN 2002

ASTM E8

The test bars used may be as cast, turned to size or machined directly from a casting depending on the customers’ requirements.

Chemical Analysis

Chemical analysis is performed using optical emission spectroscopy (OES) on a state of the art “Spectromaxx” machine.

Current capabilities allow the testing of aluminum, steel and copper based alloys. For more information on alloys analysed please go to our properties of materials page for details.

Metallography

Samples are prepared using manual and semi-automatic polishing procedures. They are analysed using a light microscope ranging from 50x to 600x magnification.

Analysis includes:

General microstructure

IGA/IGO

Porosity

Grain size

If other analysis is required contact us and we will endeavor to meet your needs.

Hardness Testing

Rockwell hardness testing is carried out per ASTM E18 and BS EN ISO 6508. Tests are performed using the Rockwell scales: HRA, HRB, HRC and HRE. The limits are often set by the material specification, but the frequency is usually set by the customers’ requirements.

Other Testing

Other tests performed by Maycast-Nokes include:

Intercrystalline

Bend

Fracture