Our services

Rapid prototyping

Rapid prototyping

We offer a flexible 3D printing service for both investment and precision sand castings.

We offer a flexible 3D printing service for both investment and precision sand castings.

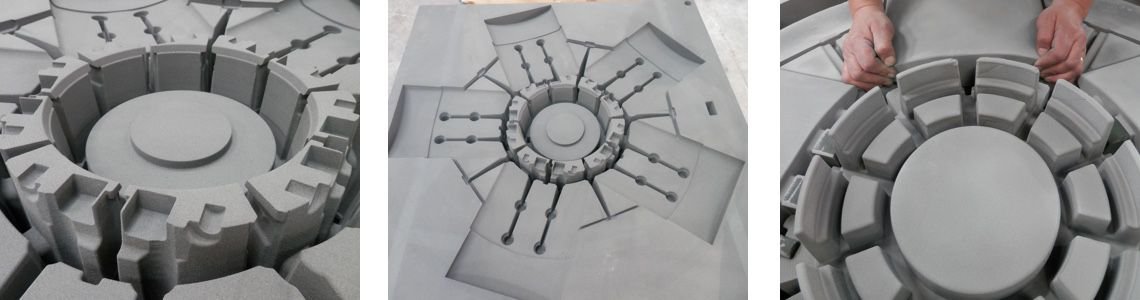

Precision Sand Casting

3D sand printing offers a number of key advantages over traditional pattern based sand casting. Printed moulds do away with the need for traditional patterns, allowing designers a far greater degree of design freedom without the need for expensive and time consuming adaptations to patterns and core boxes. The process also offers significant reductions in lead times over normal sand casting processes.

Ideal for low volume production runs and development work, printed moulds are also suitable for reverse engineering applications such as the reproduction of vintage or legacy components where only an original casting might exist. Our engineering team are able to create an accurate digital 3D model from scan data which can then be used to produce an identical casting.

We offer a variety of surface finishes to suit.